Palurec GmbH has succeeded in taking a decisive step in the recovery of PE-Alu components from used beverage cartons.

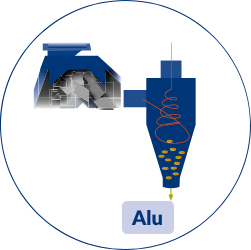

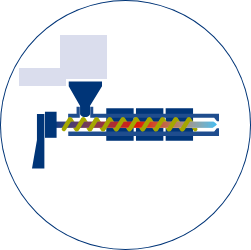

In a purely physical-mechanical process and exclusively with the help of water as a the separating agent, we produce recyclates of LDPE, HDPE and aluminium. We use standard aggregates from plastics processing and combine them in a new way.

This recycling plant increases the recyclability of the beverage carton to well over 90 %.

The Palurec procedure

PE-Alu mixture becomes new raw materials

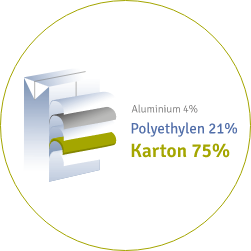

After the paper fibres have been detached, a mix of various plastics and aluminium residues are left over in the paper mills. These materials have so far been used mainly in cement factories as a low-emission fuel. It consists mainly of thin films made of polyethylene (PE) or PE-Aluminium, with which the cardboard is coated, and polyethylene (HDPE), which comes from the caps.

In addition, there are foreign substances and impurities that are not fully removed by the automatic sorting of the yellow sacks and bins.

Palurec produces secondary raw materials from this mixture that can be used in several products.

Innovative concept, proven aggregates

Low primary plastic prices are a particular challenge for the manufacturers of plastic recyclates. Apart from technical problems, this was one of the reasons why various plants for the processing of this material mixture were not previously able to prevail themselves in the long term. The Palurec plant combines already established aggregates from plastics processing into a new type of plant concept.

It is a mechanical/physical process. The separating medium is water only, no solvents are used. Palurec is the first plant of its kind in Germany to produce marketable recyclates.

The aim is to produce marketable recyclates even in a difficult market environment.

Raw materials produced

ALUMINIUM

Suitable, among other things, as an admixture for castings.

HDPE

Can be used after further processing in non-food products such as canisters, pipes, boxes etc.

LDPE

Is used as an admixture for Injection moulding applications.

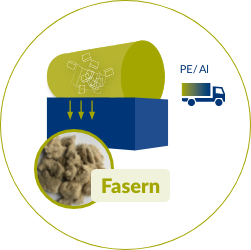

Fibre Recycling in the paper mill

Since the early 1990s, beverage cartons have been collected and recycled in paper factories in Germany – more than three million tonnes to date! Many other countries in the European Union also achieve high recycling rates.

There are now around 20 paper mills throughout Europe that use beverage cartons and recycle them using standard processes.

Beverage cartons are listed as an own waste fraction in the German and European lists of used paper types. The pulp fibres are significantly longer and more durable than most other used papers. They are therefore particularly suitable for the production of stable corrugated board packaging.

About us

Palurec GmbH was founded in December 2017. Fachverband Kartonverpackungen für flüssige Nahrungsmittel e.V. (FKN – Association for Beverage Cartons) is the sole shareholder, with its headquarters in Berlin.

There are three companies in the association, Tetra Pak GmbH (Hochheim am Main), SIG Combibloc GmbH (Linnich) and Elopak GmbH (Mannheim) which have invested around 8 million euros in the construction of the Palurec recycling plant on the site of the chemical park in Hürth near Cologne. The first stage of production will provide capacity of around 18,000 tonnes input. The plant began to operate in Spring 2021.

The member companies of FKN produce around 95% of all beverage cartons sold in Germany and have been instrumental in setting up and expanding the recycling infrastructure for used beverage cartons since the start of the Dual System. ReCarton GmbH was set up for this purpose as early as 1991; as a service provider to dual system companies. This company organises the marketing and distribution of used beverage cartons from household collections.

Press downloads

Palurec German Packaging Law Certificate

RecyClass – Recycling Process Certificate

Press photo Palurec opening with (from left) Stephen Naumann (Elopak), Robert Kummer (SIG Combibloc) and Stephan Karl (Tetra Pak)

Palurec Logo

Photo Andreas Henn

Palurec interior view

Palurec exterior view

Contact

If you have any questions about Palurec GmbH, please send us an e-mail.

We will get in touch with you as soon as possible.

E-mail: info@palurec.de

Of course, you can also reach us by phone.

Phone: (+49) 2233 – 460 608 0